CATEGORIES

- Filter Vessels

-

Sintered Porous Components

- Porous Metal Cups

- Porous Metal Discs

- Porous Metal Sheets

- Porous Metal Tubes

- Column Frits Filters

- Solvent Inlet Filters

- Pipette Filters

- Vent Filters

- Self-Sealing Filters

- Gas Diffusion Layer

- Titanium Transport Layers

- Powder Fluidizer

- Suction Canister Self-Sealing Filters

- Self-Sealing Filters for Peripheral Venous Catheters

- Self-Sealing Filters for Arterial Blood Samplers

- Filters for Humidifiers

- Filters for Oxygen Concentrators

- UHMW-PE Column Frits

- Filters for Pipette Tips

- Hot Gas Filters

-

Sintered Metal Filters

- Sintered Metal Powder Filter Cartridge

- Sintered Porous Coating Membrane Filter

- Double Layer Sintered Porous Metal Filter

- Sintered Metal Powder Sheet and Discs

- Sintered Metal Wire Mesh Filter

- Disc Shape Spargers

- Spherical Shape Sparger

- Tube Shape Spargers

- Micro Spargers

- Sintered Metal Filter Unit

- External Smooth Metal Powder Filter

- Small Diameter Metal Powder Filter

- Pharmaceutical filter disc

- Water treatment filter cartridge

- Sintered Mesh with perforated layer

- 6-Layer Sintered Mesh

- 5-Layer Sintered Mesh

- Sintered Metal Chemical Filter

- Perforated Plate Sintered Mesh Filter

- Sintered Metal Pleated Filter

- BDO Filter Disc

- Filter Cartridge for chemical fiber melt

- Sintered fiber felt without protective mesh

- Sintered fiber felt with protective meshes

- Fluidized plate for blast furnace coal injection

- FeCrAl fiber sintered felt

- Industrial Filter Elements

- Filter Systems

Related Resources

Description

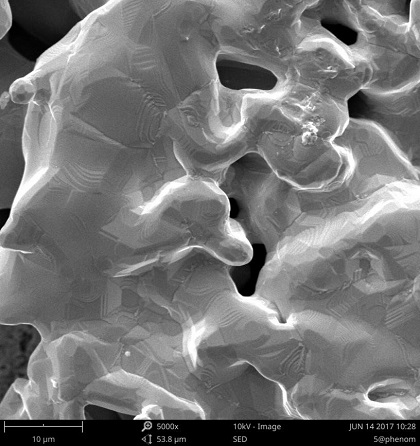

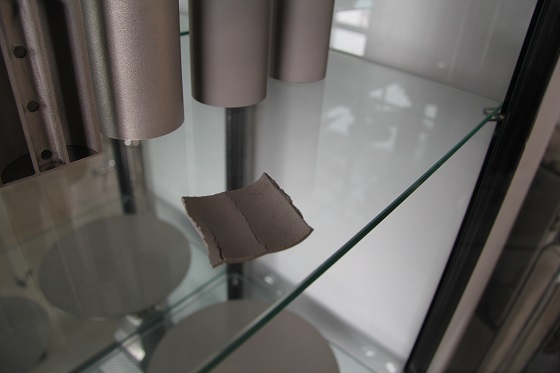

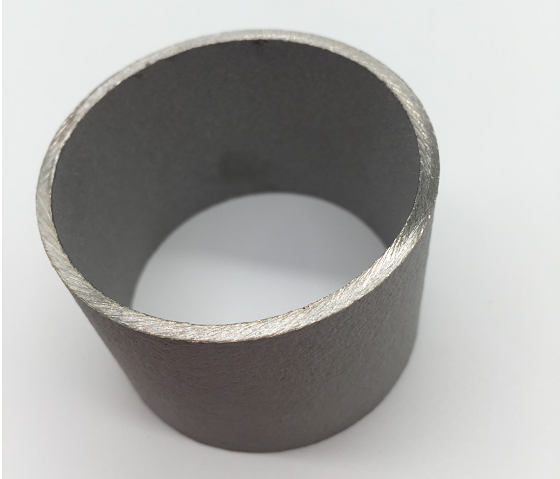

CMI sintered porous coating membrane filter is a membrane filtration product with excellent filtration effect and high permeability.

The asymmetric sintered metal powder filter contains a filter layer and a support layer. A 0.3mm thick metal film filter medium is attached to the outer surface of a porous metal film, which forms the product as a highly porous and asymmetrically filter.

The filter layer can reach 0.1micron grade. Its surface filtration characteristic brings good filtration retention in lower micron range.

Features

-Surface filtration

-Low pressure drop

-High filtration precision to 0.1μm

-High fluid flow permeability

-Easily cleaned/back-flushed

-Corrosion/abrasion resistant

-High temperature resistance, up to 900℃

-High strength and dimensional stability

-No media migration and second pollution

Data & Specifications:

-Length (without welding): <1500mm

-Outside Diameter(OD): 56mm-64mm

-Media Grade: 0.1-3 μm

Note: Special material, sizes and shape can be customized

Product Material:

-Stainless Steel (SS316L, 304L,310S,904L)

-Titanium

-Hastelloy (C-22,C-276,XB-2)

-Inconel (600, 625,800)

-Monel (400 and so on)

-Nikel

Applications:

-Petrochemical Industry

- Decarbonization filtration and precision filtration of liquid products, liquid raw materials and pharmaceutical intermediates in chemical industry

- Filtration and recovery of ultrafine crystals and catalysts

- Precise filtration after resin adsorption and impurity removal filtration of heat conducting oil and materials

- Field return water filtration

-Water treatment Industry

- Security filtration of ultrafiltration, RO and EDI systems in water treatment industry, filtration after ozone sterilization, and before canning

- Security filtration before reverse osmosis in seawater desalination field

-Pharmaceutical Industry

- Decarbonization filtration of large infusion, small injection and concentrated oral liquid and security filtration before terminal filtration of dilute liquid

- Impurity removal and filtration in the production process of bulk medicine, decarbonization and fine filtration of materials

-Food Industry

- Clarification and filtration of beverage, fruit juice, liquor, beer, mineral water, soy sauce and vinegar

-In all of these industrial above

- Material interception and filtration in vacuum feeding system (titanium filter element can prevent powder material leakage and environmental pollution)

- Gas purifications of steam, compressed air, catalytic gas filtration

|

|

|

|