CATEGORIES

- Filter Vessels

-

Sintered Porous Components

- Porous Metal Cups

- Porous Metal Discs

- Porous Metal Sheets

- Porous Metal Tubes

- Column Frits Filters

- Solvent Inlet Filters

- Pipette Filters

- Vent Filters

- Self-Sealing Filters

- Gas Diffusion Layer

- Titanium Transport Layers

- Powder Fluidizer

- Suction Canister Self-Sealing Filters

- Self-Sealing Filters for Peripheral Venous Catheters

- Self-Sealing Filters for Arterial Blood Samplers

- Filters for Humidifiers

- Filters for Oxygen Concentrators

- UHMW-PE Column Frits

- Filters for Pipette Tips

- Hot Gas Filters

-

Sintered Metal Filters

- Sintered Metal Powder Filter Cartridge

- Sintered Porous Coating Membrane Filter

- Double Layer Sintered Porous Metal Filter

- Sintered Metal Powder Sheet and Discs

- Sintered Metal Wire Mesh Filter

- Disc Shape Spargers

- Spherical Shape Sparger

- Tube Shape Spargers

- Micro Spargers

- Sintered Metal Filter Unit

- External Smooth Metal Powder Filter

- Small Diameter Metal Powder Filter

- Pharmaceutical filter disc

- Water treatment filter cartridge

- Sintered Mesh with perforated layer

- 6-Layer Sintered Mesh

- 5-Layer Sintered Mesh

- Sintered Metal Chemical Filter

- Perforated Plate Sintered Mesh Filter

- Sintered Metal Pleated Filter

- BDO Filter Disc

- Filter Cartridge for chemical fiber melt

- Sintered fiber felt without protective mesh

- Sintered fiber felt with protective meshes

- Fluidized plate for blast furnace coal injection

- FeCrAl fiber sintered felt

- Industrial Filter Elements

- Filter Systems

Description

Fine-grained bulk materials such as flour, cement, pigments, milk powders are often difficult to be stored, mixed and discharged because these fine-grained powders do not flow freely. They tend to agglomerate and form bridges or tunnels around the outlet and therefore, can only be removed effectively with some sorts of aids.

CMI develops sintered metal fluidizer which can solve this problem.

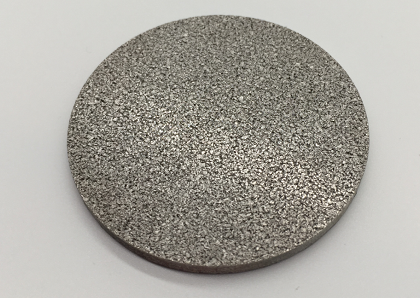

The porous metal fluidizers are manufactured from isostatic cool pressing and high temperature vacuum sintering. It is a special application of modern fluidized bed technology for the treatment of bulk material of small particle sizes. Porous bottom or aeration units are assembled at the inner surface of bins and silos. Air is blown into the bin through the whole area of these porous units to fluidize the stored bulk material, to set it into a liquidlike state. Then caking or discharge problems can be solved. Besides that, the unit can also work as mixing or homogenization beds, thereby avoiding the need of additional discharge elements.

Features

-Even air distribution across the entire surface

-Constructive simple solutions

-Specific selectable pore size

-High mechanical strength

-Good chemical resistance

-Simple installation

-Good corrosion resistance

Data & Specifications:

We can customize products acc. to specific requirements:

- Material required

- Micron rating required

- Operation Temperature

- Dimensions and tolerances

- Hardware and fittings to be connected

Product Material:

-Stainless Steel (SS316L, 304L,310S,904L)

-Titanium

-Hastelloy (C-22,C-276,XB-2)

-Inconel (600, 625,800)

-Monel (400 and so on)

-Nikel

Note: Special material, sizes and shape can be customized. Pls. contact CMI at sales@cmi-ly.com if you have more exacting requirements.