CATEGORIES

- Filter Vessels

-

Sintered Porous Components

- Porous Metal Cups

- Porous Metal Discs

- Porous Metal Sheets

- Porous Metal Tubes

- Column Frits Filters

- Solvent Inlet Filters

- Pipette Filters

- Vent Filters

- Self-Sealing Filters

- Gas Diffusion Layer

- Titanium Transport Layers

- Powder Fluidizer

- Suction Canister Self-Sealing Filters

- Self-Sealing Filters for Peripheral Venous Catheters

- Self-Sealing Filters for Arterial Blood Samplers

- Filters for Humidifiers

- Filters for Oxygen Concentrators

- UHMW-PE Column Frits

- Filters for Pipette Tips

- Hot Gas Filters

-

Sintered Metal Filters

- Sintered Metal Powder Filter Cartridge

- Sintered Porous Coating Membrane Filter

- Double Layer Sintered Porous Metal Filter

- Sintered Metal Powder Sheet and Discs

- Sintered Metal Wire Mesh Filter

- Disc Shape Spargers

- Spherical Shape Sparger

- Tube Shape Spargers

- Micro Spargers

- Sintered Metal Filter Unit

- External Smooth Metal Powder Filter

- Small Diameter Metal Powder Filter

- Pharmaceutical filter disc

- Water treatment filter cartridge

- Sintered Mesh with perforated layer

- 6-Layer Sintered Mesh

- 5-Layer Sintered Mesh

- Sintered Metal Chemical Filter

- Perforated Plate Sintered Mesh Filter

- Sintered Metal Pleated Filter

- BDO Filter Disc

- Filter Cartridge for chemical fiber melt

- Sintered fiber felt without protective mesh

- Sintered fiber felt with protective meshes

- Fluidized plate for blast furnace coal injection

- FeCrAl fiber sintered felt

- Industrial Filter Elements

- Filter Systems

Related Resources

Description

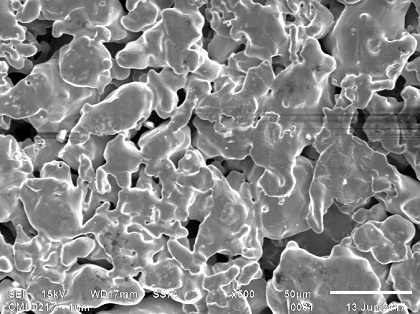

CMI manufactures sintered metal powder filter cartridges in a wide range of materials, sizes and connections to meet the characteristics and configurations that customers need.

Sintered porous metal filters are manufactured from isostatic cool pressing and high temperature vacuum sintering. The micron rating and distribution of the pores can be controlled by the metal powder. They are ideal choice for process filtration applications where high strength and excellent corrosion and temperature resistance are required.

Features

-Precise pore size distributions

-High fluid flow permeability

-Easily cleaned/back-flushed

-Corrosion/abrasion resistant

-High temperature resistance, up to 900℃

-High strength and dimensional stability

-No media migration and second pollution

Data & Specifications:

-Length: <1600mm

-Outside Diameter(OD): 4mm-450mm

-Media Grade: 0.3-100 μm

Note: Special material, sizes and shape can be customized

Product Material:

-Stainless Steel (SS316L, 304L,310S,904L)

-Titanium

-Hastelloy (C-22,C-276,XB-2)

-Inconel (600, 625,800)

-Monel (400 and so on)

-Nikel

Applications:

-Petrochemical Industry

- Decarbonization filtration and precision filtration of liquid products, liquid raw materials and pharmaceutical intermediates in chemical industry

- Filtration and recovery of ultrafine crystals and catalysts

- Precise filtration after resin adsorption and impurity removal filtration of heat conducting oil and materials

- Field return water filtration

-Water treatment Industry

- Security filtration of ultrafiltration, RO and EDI systems in water treatment industry, filtration after ozone sterilization, and before canning

- Security filtration before reverse osmosis in seawater desalination field

-Pharmaceutical Industry

- Decarbonization filtration of large infusion, small injection and concentrated oral liquid and security filtration before terminal filtration of dilute liquid

- Impurity removal and filtration in the production process of bulk medicine, decarbonization and fine filtration of materials

-Food Industry

- Clarification and filtration of beverage, fruit juice, liquor, beer, mineral water, soy sauce and vinegar

-In all of these industrial above

- Material interception and filtration in vacuum feeding system (titanium filter element can prevent powder material leakage and environmental pollution)

- Gas purifications of steam, compressed air, catalytic gas filtration

|

|

|

|