Quality Control

Certified by ISO9001:2008

Quality control has to be done from raw material to part-finished products until final product inspection.

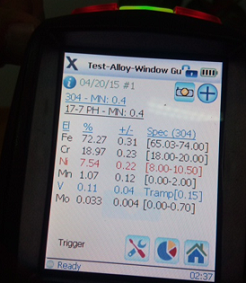

Raw Material Control

- Identify metal element with latest technology for steel plates, pipes, elbows, casting parts and so on

- For porous metal products: Separate raw material into different grade by our own tools instead of leaving this part to supplier

- Loose Density Inspection: loose density means weight of unit volume in no pressure condition. It decides the consistency of pore size. This inspection is to make sure the pore size is good and consistent

Production Control

- Mold Control: Specific mold will be applied for filter elements

- Welding Control: Welder certificates are updated every period; Besides welding of standard metal, for porous metal, we have our own special welding facilities.

- Inspection of half-finished products: inspection of rough dimensions during half finished step to make sure the production can be continued.

- Records of each step will be done for future checking in case of quality problems

Contamination Control:

- Working Condition control, clean and inspection with grooves for filter elements

- Make sure raw material of filter elements are packed well and sealed

- Porous filters are sintered in vacuum oven

- Mold of filter elements are mainly alloy

Final Inspection:

- For normal filter elements, ventilate test has to be done

- For sintered metal filters, bubble test has to be done

- For filter vessels, pressure test has to be done acc. to drawing and kept for at least 30minuts

Packing& Shipping:

- Seaworthy package for sea shipment

- Plywood package suitable for export