CATEGORIES

- Filter Vessels

-

Sintered Porous Components

- Porous Metal Cups

- Porous Metal Discs

- Porous Metal Sheets

- Porous Metal Tubes

- Column Frits Filters

- Solvent Inlet Filters

- Pipette Filters

- Vent Filters

- Self-Sealing Filters

- Gas Diffusion Layer

- Titanium Transport Layers

- Powder Fluidizer

- Suction Canister Self-Sealing Filters

- Self-Sealing Filters for Peripheral Venous Catheters

- Self-Sealing Filters for Arterial Blood Samplers

- Filters for Humidifiers

- Filters for Oxygen Concentrators

- UHMW-PE Column Frits

- Filters for Pipette Tips

- Hot Gas Filters

-

Sintered Metal Filters

- Sintered Metal Powder Filter Cartridge

- Sintered Porous Coating Membrane Filter

- Double Layer Sintered Porous Metal Filter

- Sintered Metal Powder Sheet and Discs

- Sintered Metal Wire Mesh Filter

- Disc Shape Spargers

- Spherical Shape Sparger

- Tube Shape Spargers

- Micro Spargers

- Sintered Metal Filter Unit

- External Smooth Metal Powder Filter

- Small Diameter Metal Powder Filter

- Pharmaceutical filter disc

- Water treatment filter cartridge

- Sintered Mesh with perforated layer

- 6-Layer Sintered Mesh

- 5-Layer Sintered Mesh

- Sintered Metal Chemical Filter

- Perforated Plate Sintered Mesh Filter

- Sintered Metal Pleated Filter

- BDO Filter Disc

- Filter Cartridge for chemical fiber melt

- Sintered fiber felt without protective mesh

- Sintered fiber felt with protective meshes

- Fluidized plate for blast furnace coal injection

- FeCrAl fiber sintered felt

- Industrial Filter Elements

- Filter Systems

Related Resources

Sintered Metal Pleated Filter

Description

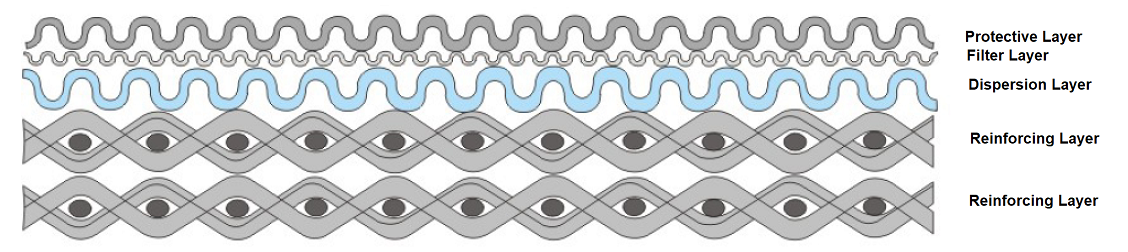

CMI sintered metal pleated filter is a kind of filter made by multiple layers of sintered mesh panels or sintered fiber panels. Several layers of metal mesh or fiber are heated, pressed and bonded together by high temperature vacuum sintering, argon arc or plasma welding. Then cut, pleated into filter element. This medium has excellent heat resistance, pressure resistance, and corrosion resistance, and it is used for high temperature, high viscosity fluid filtration.

Sintered pleated filter is a typical depth filtration structure that can provide high filtration efficiency, low resistance, and large contaminant retention capability. It gives outstanding performance, especially in the removal of gel contaminants in high molecular polymer. These filtration properties ensure product quality during manufacturing processes and extended filter life. All these adds up to higher productivity and lower on maintenance costs.

Besides sintered metal mesh filter cartridges, sintered mesh or fiber panels can also be formed into other filter elements like sintered metal mesh filter discs, sintered wire mesh cylinders, sintered wire mesh cones and tubes.

Features

- Excellent resistance to high temperatures, low temperatures and thermal shock

- Excellent mechanical strength and impact resistance

- Excellent uniformity of filtration pores

- Big flow rate of unit surface area

- Applied in high pressure or high viscosity environment

- Corrosion and high temp. resistant

- Filters are washable and reusable when necessary

- Excellent machinability allows a wide range of configurations

- Bigger filtration area compared with plain types

Data & Specifications:

- Outside Diameter of cartridges(OD): 20mm, 30mm, 50mm, acc. To customer request

- Length(inch): 10, 20, 30, 40, 50, 60, 70, acc. To customer request

- Media Grade: 1-300 μm

- Operation Temperature: -269℃ to 480℃

- Dirt Holding capacity: 16.9-41mg/cm²

- End connections: standard connections like 222,220,226, quick connection, thread connection, flange connections, tie rod connections and so on.

Cross section Structure of sintered mesh filter (different products have different layers)

Product Material:

-Stainless Steel (SS316L, SS304)

Applications:

-Purification and Filtration of Liquid & Gas

-Separation and recovery of solid particle

-Transpiration cooling under high temperature

-High Polymer Industrial

-Aviation/Marine/Machinery

-Chemical fiber filtration

-Chemical Processing