CATEGORIES

- Filter Vessels

-

Sintered Porous Components

- Porous Metal Cups

- Porous Metal Discs

- Porous Metal Sheets

- Porous Metal Tubes

- Column Frits Filters

- Solvent Inlet Filters

- Pipette Filters

- Vent Filters

- Self-Sealing Filters

- Gas Diffusion Layer

- Titanium Transport Layers

- Powder Fluidizer

- Suction Canister Self-Sealing Filters

- Self-Sealing Filters for Peripheral Venous Catheters

- Self-Sealing Filters for Arterial Blood Samplers

- Filters for Humidifiers

- Filters for Oxygen Concentrators

- UHMW-PE Column Frits

- Filters for Pipette Tips

- Hot Gas Filters

-

Sintered Metal Filters

- Sintered Metal Powder Filter Cartridge

- Sintered Porous Coating Membrane Filter

- Double Layer Sintered Porous Metal Filter

- Sintered Metal Powder Sheet and Discs

- Sintered Metal Wire Mesh Filter

- Disc Shape Spargers

- Spherical Shape Sparger

- Tube Shape Spargers

- Micro Spargers

- Sintered Metal Filter Unit

- External Smooth Metal Powder Filter

- Small Diameter Metal Powder Filter

- Pharmaceutical filter disc

- Water treatment filter cartridge

- Sintered Mesh with perforated layer

- 6-Layer Sintered Mesh

- 5-Layer Sintered Mesh

- Sintered Metal Chemical Filter

- Perforated Plate Sintered Mesh Filter

- Sintered Metal Pleated Filter

- BDO Filter Disc

- Filter Cartridge for chemical fiber melt

- Sintered fiber felt without protective mesh

- Sintered fiber felt with protective meshes

- Fluidized plate for blast furnace coal injection

- FeCrAl fiber sintered felt

- Industrial Filter Elements

- Filter Systems

Related Resources

Description

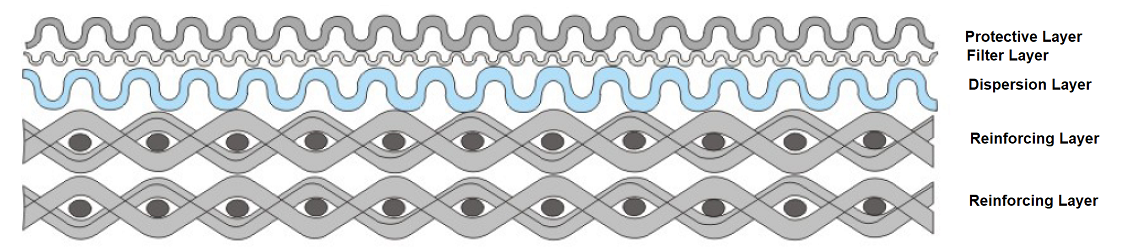

The structure of standard five-layer sintered mesh is composed of four parts: protective layer, filter layer, dispersion layer and skeleton layer. The filter material not only has uniform and stable filtration precision, but also has high strength and rigidity. It is an ideal filter material for occasions that require high compressive strength and uniform filtration precision. Because it is surface filtration, and the mesh channel is smooth, it has good backwash regeneration performance and can be used repeatedly for a long time, especially suitable for continuous and automatic operation processes. The material is easy to form, process and weld, and can be processed into various forms of filter elements such as round, cylindrical, conical and corrugated.

Features

1. Good strength and rigidity: good mechanical strength and compressive strength, good processing, welding and assembly performance, easy to use

2. Uniform and stable precision: Uniform and consistent filtration performance can be achieved for all filtration precisions, and the mesh will not be reformed during use.

3. Wide range of applications: it can be used for filtration in temperature environments from -200°C to 600°C and in acid-base environments

4. Excellent cleaning performance: It can be used repeatedly, and has a long service life (can be cleaned by countercurrent water, filtrate, ultrasonic, dissolution, baking, etc.).

Structure:

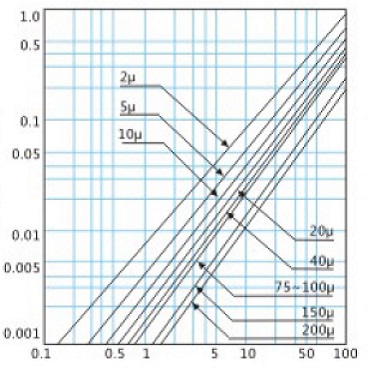

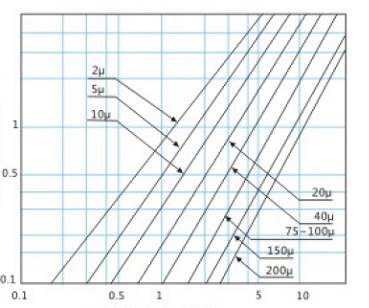

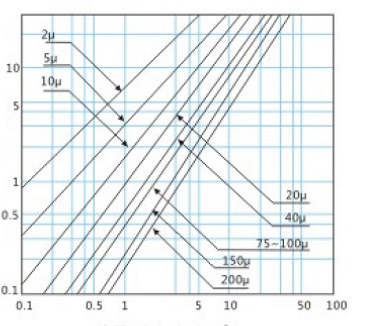

DP and flow chart:

Dp (kgf/cm2) and flow (L/min/cm2) by Air

Dp (kgf/cm2) and flow (L/min/cm2) by Water

Dp (kgf/cm2) and flow (L/min/cm2) by Oil Media

SPEC. and Material:

1, Material: SS304, SS316L, Special material like Hastelloy, Monel, 904L can also be made acc. To request.

2, Main spec.:

1000mm*500mm

1000mm*600mm

1000mm*1000mm

1200mm*1000mm

1200mm*1200mm

3, Filtration Rating: 1-300μm